Association Website Engineering Page July/August

The intention is to provide a monthly update of what is going on in the engineering workshop of the SDR.

South Devon Railway Engineering Ltd is a wholly owned subsidiary of the South Devon Railway Trust. The profits it makes are returned to the Trust.

Firstly let's introduce the paid staff

- Rob Le Chevalier (Workshop Manager)

- Ray Lee (Running Shed Foreman)

- Ian Salt

- Nick Davies

- John Orme

- Martin Harvey

- Steve Trenouth

|

| Tea break in the mess room |

Whilst it is true that some workshop tasks, such as operating the vertical boring machine, are carried out only by trained staff a great deal of the work is carried out by volunteers working alongside paid staff.

The workshop paid staff and volunteers alike are astonishingly adaptable and inventive. It is a credit to the management that the SDR has put together such a highly skilled team. The staff and volunteers have between them an enormous range of knowledge, not just relating to steam locomotives, but to a wide range of general engineering. Anyone visiting the workshop will be immediately impressed by the enthusiasm and team spirit displayed. Perhaps what is most remarkable is the shared ambition to overcome any almost any problem. The positive determined atmosphere is infectious and anyone volunteering regardless of their initial skill level will find themselves given training and with it a surprising amount of responsibility. A large part of the success of SDR Engineering Ltd has undoubtedly been down to the readiness of the management to recognise abilities, provide training and delegate responsibility. There is very little, if any, blame culture but a readiness to accept that inevitably sometimes things go wrong, to learn and move on.

The workshop now boasts a very comprehensive facility for replacing tyres and machining wheels. To this end the workshop has, a wheel drop, an 8 foot diameter vertical boring machine, two wheel lathes one of which is CNC operated, a quartering machine for machining crank pins, a Gibson ring rolling machine and a large and very powerful press for removing and pressing wheels onto axles. The workshop also boasts a comprehensive range of other machine tools such as lathes, milling, boring and grinding machines as well as a 100 ton hydraulic press. In addition there is a very useful range of heavy lifting equipment including overhead cranes, a fork lift and a large capacity road going crane.

|

| Road going heavy lifting crane |

|

| General view of the part of the workshop concerned with wheels |

|

| Heating equipment used for expanding tyres prior to cooling and shrinking them onto wheels. |

|

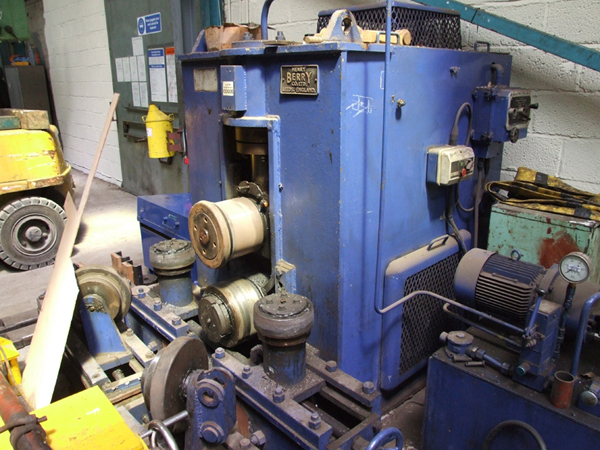

| Gibson ring rolling machine |

|

| 8 foot diameter table of vertical boring machine |

|

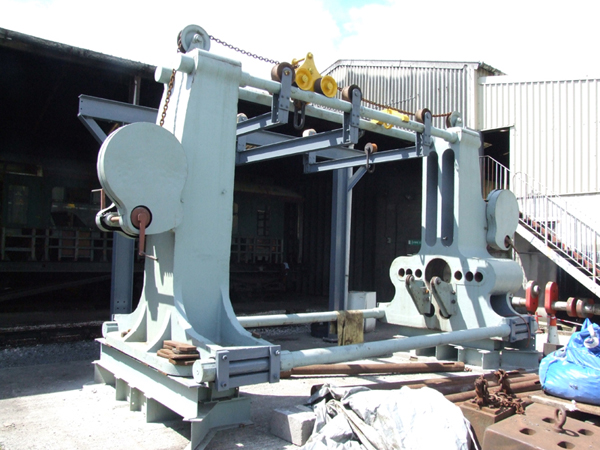

| Wheel press ready to receive refurbished hydraulic ram |

|

| 100 ton hydraulic press |

A wagon turntable has recently been restored by John Medcalf one of our dedicated volunteers (John has also been responsible for a significant proportion of the restoration of the wheel press) . This small turntable was acquired from the old Austin Morris plant at Oxford in 2001.

|

| Wagon turntable awaiting installation |

The turntable will enable boilers to be temporarily mounted on substantial trolleys and moved easily around the site. Whilst on the subject of volunteers it would be unreasonable not to make early mention of Clive Pepper who has been responsible for a great deal of the design work that has gone into so many of the workshop projects such as the design of the building extensions, the coal elevator and all manner of other theoretical work. Through the following months I shall try to introduce a few more of the invaluable and talented volunteers whose contributions have been essential to the advance of SDR Engineering.

In future there will be very little steam locomotive work that the SDR will not be able to undertake apart from foundry work. It would not be unreasonable to look forward to a time, quite soon now, when SDR Engineering Ltd becomes a very significant player indeed in the world of contract steam restoration.

Work Underway

6412 (Pannier tank recently purchased from the West Somerset Railway Association)

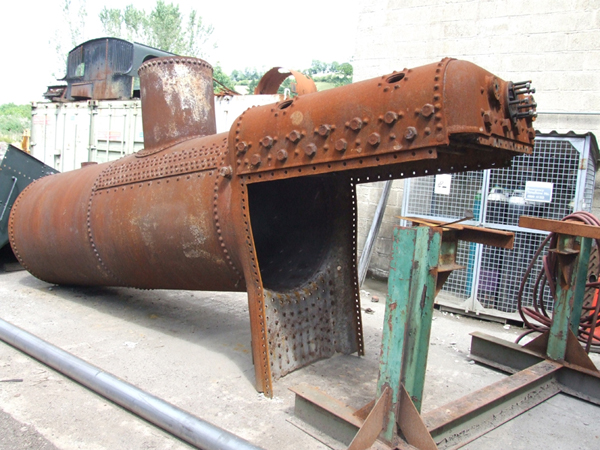

The decision has been made to restore 6412 over the next 18 months. 6412 came to us more as a collection of parts rather than a complete loco. It is ahead of the other locos awaiting restoration, such as 1420, because not only is it an ideal loco for our line but we are eager to assemble it to ensure that nothing is missing. A lot of money has been raised to enable its purchase and therefore understandably there is a lot of interest in seeing its early restoration. Its boiler, wheels and motion have been removed from the frames which have been rubbed down and are now being repainted. The reprofiling of the wheels is now almost complete.

|

| 6412 boiler awaiting repairs |

|

| Frames of 6412 ready for repainting |

It is anticipated that the axle boxes will be re-metalled in the next month and the newly turned wheels returned to the frames. Also the various other parts of the motion such as the eccentrics will be refurbished and returned to the frames in the very near future.

69621 N7 Tank

This is a contract job for the East Anglian Railway Museum. This loco has been based on the North Norfolk Railway and is in the workshop for attention to cracked axle boxes. Two of the axleboxes have been sent away so that patterns can be made and new axleboxes cast. Inspection of the loco continues and when the axle boxes are delivered and machined the loco will be reassembled and tested before returning to Norfolk. Hopefully no other serious faults will be discovered and this job can proceed relatively quickly.

|

| 69621 over the wheel drop |

|

| Nick Davies dismantling a radial axle box assembly of 69621 |

3205

This loco has been reassembled painted and tested and is now in service. Whilst on test I found the loco to be well up to its previous performance and it is a credit to the quality of the work carried out in our workshop. There are one or two minor teething problems which are presently being addressed.

LO52 "Yorky" Yorkshire diesel shunter

The Yorky's engine/ generator unit has been removed and the engine is being rebuilt with new pistons and undergoing a general overhaul. It is anticipated that this job will take about three weeks depending on delivery time of replacement parts.

|

| "Yorky's" diesel engine and generator set |

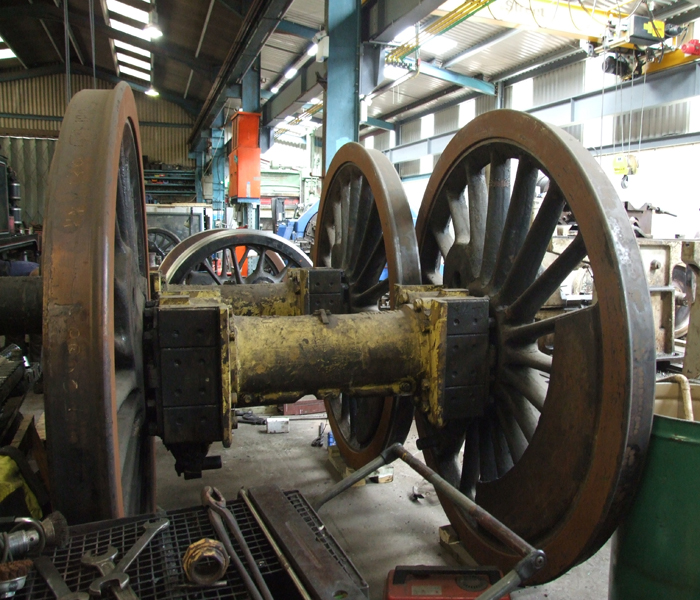

Wheel sets from Camelot (73082 BR Standard Class 5) based on the Bluebell Railway and owned by the Camelot Locomotive Society.

These wheel sets have had their tyres replaced and are awaiting the completion of the wheel press so that the wheels may be removed and the Cannon axle boxes serviced. When the wheels are returned to the axles the tyres will then be turned to their correct profile in the large wheel lathe.

|

| Camelot's driving wheels showing Cannon axleboxes |

Maunsell Wheel Set (from Bluebell Railway Coach)

Originally all four wheel sets were delivered to SDR Engineering for journal reprofiling. Three were machined and returned but the fourth was unfortunately discovered to have a cracked axle. This will require the wheel to be pressed off and a new steel axle forging obtained from South Africa. This will be then machined and the wheels pressed back on before final reprofiling.

|

| Maunsell carriage wheel set showing teak inserts |

Recently smoke box front plate and petticoat pipe have been manufactured to Clive Pepper's drawings for 9682 (GWR 0-6-0 Pannier tank based at the Southall Railway Centre). SDR Engineering will be able to produce more of these 0-6-0 PT parts at the following prices :- Smokebox front plate £2480 and petticoat pipe £167 (plus VAT at current rate.).

|

| Rob Le Chevalier showing off the smokebox front plate for 9682 |

|

| 9682 petticoat pipe |

Forthcoming work

Contract work to manufacture Side tanks for 9466 This work is likely to start in September

1420

I am sure that there is a great deal of interest in the return of this much loved loco to our line. Unfortunately it will require a considerable amount of work. The boiler work will be a major undertaking with only the boiler barrel, front tube plate, inner firebox and crown wrapper being reusable. The side tanks will also need to be replaced completely. Nevertheless its restoration is very much in mind with a possible completion target of 2015.

5786

This extremely versatile and powerful loco should continue until September 2011 depending on the annual boiler examination. It is still in excellent condition and when at the end of its ticket it is intended to do a boiler lift and attend to any other problems before returning to service in 2012. This job will run alongside the continuing restoration of 6412.

Other Motive Power news

5526

Is running well and has until 2013 before the boiler requires removal for examination.

3803

This locomotive has performed well on our line and has become a favourite among several members of the Footplate Dept. Unfortunately it is thought to be too large for our needs and has been put up for sale with the hope that a deal could be struck such with another railway so that we obtain a more suitable locomotive possibly with a cash adjustment. On 24th May 3803 went on hire to the Gloucester and Warwickshire Railway and, unless sold in the meantime, will return to us at the end of September.

1369

This loco is also earning us valuable income on hire to the Chinnor and Princess Risborough Railway. It is expected that it will return to us next year. It is proving to be a great favourite at Chinnor. Our engineering staff visit regularly to perform boiler washouts.

4920 Dumbleton Hall

It is good to see this locomotive on display earning its keep as a static display opposite the platform at Buckfastleigh. Credit must go to those dedicated enthusiasts that try to keep the locomotive looking as smart as possible.

Officially 4920 is awaiting heavy general overhaul and there is no technical reason why we could not perform the work when the time is right.

Bob Vaughton