Ever wondered why the flanged edge of a railway wheel is called a tyre ?

Well the wearing surface is a separate entity which has good wear properties and, to keep the costs down, is replaceable.

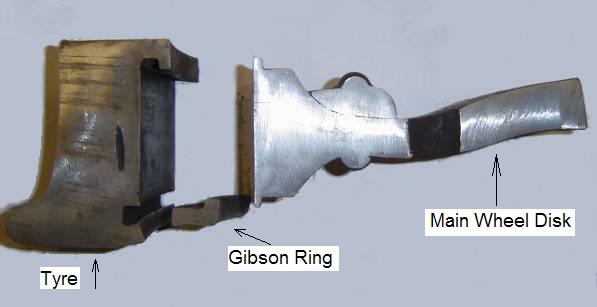

The tyre is heated to expand it and then the wheel is lowered into it. Whilst still hot a circlip, called a "Gibson ring" is sprung into the recess in the back of the tyre. To hold this in place the back of the tyre is rolled down to crimp the tyre in place.

The sectioned wheel below illustrates the component parts.

Carriages and wagons use external axle boxes on the ends of the axle shaft whereas most locomotive journals are inside the wheels because of the connecting rods.

Details of the Gibson ring press are below along with pictures of the tyre heating ring from the former GWR workshops in Swindon.

Well the wearing surface is a separate entity which has good wear properties and, to keep the costs down, is replaceable.

The tyre is heated to expand it and then the wheel is lowered into it. Whilst still hot a circlip, called a "Gibson ring" is sprung into the recess in the back of the tyre. To hold this in place the back of the tyre is rolled down to crimp the tyre in place.

The sectioned wheel below illustrates the component parts.

Carriages and wagons use external axle boxes on the ends of the axle shaft whereas most locomotive journals are inside the wheels because of the connecting rods.

Details of the Gibson ring press are below along with pictures of the tyre heating ring from the former GWR workshops in Swindon.

|

| A section through an assembled railway wheel |

|

| The component parts of a railway wheel |

In the photograph above you'll notice the edge of the tyre is bent over onto the Gibson ring. This is done using a special press as in the next photographs.

|

| Wheelset mounted in the Gibson Ring press (note rollers adjust to compensate for wheel diameter). |

|

| Close up of the rolling action |