SOUTH DEVON RAILWAY GWR Window Door Skin

| |

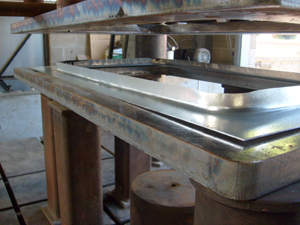

| Freshly pressed GWR door skins in SDRE Works | Photo © GBishop 2012 |

South Devon Railway Engineering have just added these pressings to their growing list of parts for the heritage rail industry.

Whilst more used to pressing boiler backheads from red hot 10mm thick boiler plate boilersmith Peter Bowden has built all the tooling to enable these items to be pressed cold from 2mm galvanised steel using the John Shaw 700 ton vicing press which really doesn’t know there’s anything going on !

The use of the slightly thicker 2mm galvanised steel (instead of the normal 1.6mm sheet) allows for a full draw in each corner meaning no fabrication is needed and these are the finished article saving a lot of time and additional expense.

The great advantage of using a vicing press is that the press first grips the workpiece firmly, with 100 tons force, preventing the blank moving whilst the punch is powered through using separate rams. In this case Peter used just the centre ram.

The lock hole is not provided in case the lock is not in the standard location. Also the hinge notches are not present to allow for variations in the individual doors.

The first SDR coach to benefit from these new door skins is Hawksworth brake third W2180 for which the London Group are grateful since 2180 needs six new door top skins..

|  |

| Punch raised through the die | Finished door skin in press |

|  |

| SDRE’s 700 ton John Shaw vicing press with die and punch | W2180’s door 10 reskinned |

| Photos top and lower left © SDRE 2012 | Photo lower right © GBishop 2012 |

These skins are designed to fit standard Hawksworth carriage doors with drop light i.e. GWR carriages designed or modified by Hawksworth. Carriages on the SDR that will benefit include 7377, 276, 1645 and certain doors on the autos 225, 228 & 240.

For further details, such as how to order, please click here.